- We are very close to you!

- 0 532 264 91 04

- info@enpotek.com

Textured (Orange Pattern) Epoxy Floor

11 March 2024Tennis Court Coating

11 March 2024Self Leveling Epoxy Floor Application

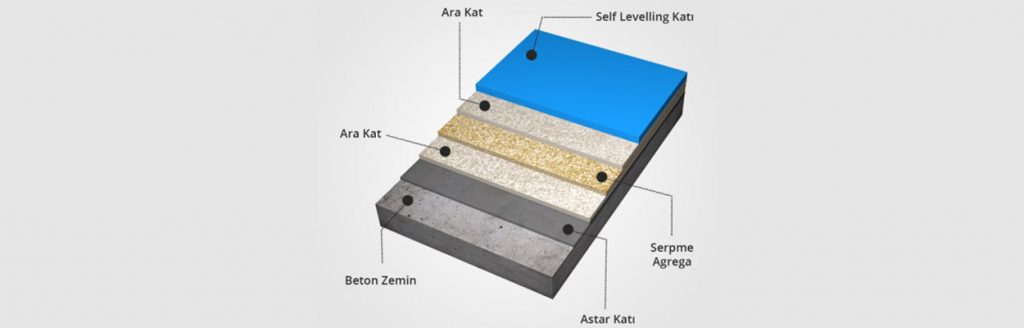

It is the epoxy type with very smooth surface appearance, very durable, aesthetic and decorative features. Resistant to chemicals, abundant colour variety, cleaning is very event, hygienic, epoxy floor covering. It is especially preferred where cleaning costs are high, it has high performance. Self Levelling Epoxy Floor Coating is a floor covering that is easy to clean and does not hold dust. It is easy to clean and has moderate mechanical strength and chemical resistance. Self Levelling Epoxy Floor Coating is a type of floor coating that makes new concrete floors or worn, pitted, damaged concrete floor surfaces shiny, dense and smooth. With this chemical coating, floors can be formed in a fast, durable way. The floor covering becomes ready for walking on it approximately one day after it is made. It should not be exposed to heavy loads by waiting 7 days for full mechanical and chemical resistance.

Self Levelling Epoxy Flooring Usage Areas

Self Levelling Epoxy Flooring can be used in all industrial flooring, pharmaceutical factories, hospitals, chemical factories, hospitals, electrical factories, machinery factories, food production facilities, chemical factories, textile factories, clothing workshops, plastic production facilities, exhibition halls, automotive sector and all warehouses with different colour preferences.

SELF LEVELING EPOXY FLOOR DURABILITY

It is resistant to dilute acids, dilute and concentrated alkalis, cleaning detergents and disinfectants, vegetable, mineral and animal oils, fresh water and sea water, diesel, petrol, alcohol and many other solvents. In addition, it is resistant to 50°C in wet environment and 130°C in dry environment continuously without being under chemical and mechanical factors. Self Leveling epoxy floor application is also applied as transparent epoxy and is preferred in customer-oriented choices.

SELF LEVELING EPOXY FLOOR Features

- Cleanroom (clean room) certificate can be used on all floors in contact with food.

- It falls into the middle thickness class.

- Thickness varies between 1-4 mm.

- It is suitable for your budget as application prices.

- Smooth surface is moderately resistant to friction, abrasion and impact.

- It has the ability to be easily cleaned.

- Anti-bacterial feature.

- Waterproof, dust-proof.

- Repair, easy maintenance and cheap prices.

- This application can be done with transparent epoxy.

- High adhesion to the floor.

- Epoxy Floor Coating system is preferred on floors with heavier pedestrian, vehicle and forklift traffic than epoxy coating system.

- It is easy to clean and dust-free floor covering in pharmaceutical factories, hospitals, power plants.

- It is resistant to the effect of chemical substances.